Home >> PRODUCTS >> Mud Non Landing System

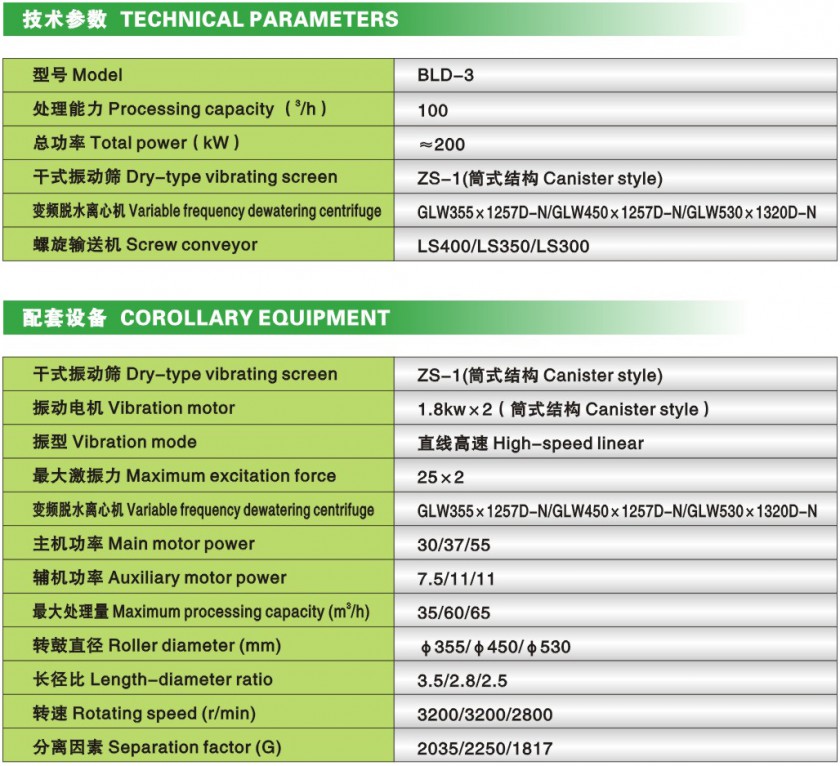

This system separates the drilling cuttings from the mud through a linear vibrating screen and a high-frequency centrifuge, controls the water content of the cuttings, achieves the goal of harmless treatment of the mud, and meets the requirements of secondary recycling and utilization, saving drilling costs. It can be processed synchronously with the drilling process, including on-site separation, on-site treatment, on-site recycling, and on-site production of finished products. Integrate mature technologies both domestically and internationally, achieve effective utilization of drilling fluid on site, and solve the problem of ineffective and harmless treatment of drilling fluid. Main features: Solved the technical problems of high material requirements, high energy consumption, high operating costs, and high maintenance costs in the existing technology of solid-liquid separators. The treatment process is simple, the operation is stable and reliable, there is no noise, the energy consumption is low, and the operation is convenient. Low requirements for materials, simple structure, and convenient disassembly. The equipment processing unit can be modular combined according to different mud volumes, adapting to various processing volumes. The beneficial phase separated from the equipment can be directly returned to the drilling fluid preparation system, saving drilling and mining costs. This equipment produces no pollutants during the processing and production process, achieving zero pollution and zero emissions.

|